Guidelines on a Control Model

This Control Model is a long time in use – which shows how useful it is. While it looks rather complicated, when you do indeed sit down and start using the concept with all the components, you will see its great benefits.

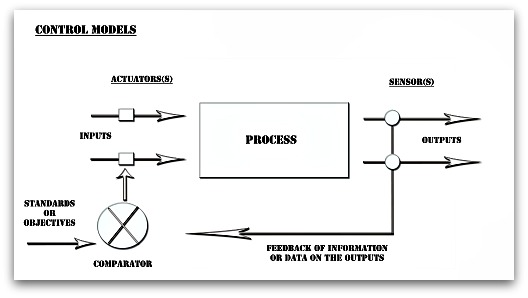

Similar to Input-Output diagrams, you now add sensors to the outputs. These are some means or method of comparing the outputs from your process to a standard or an objective. The question in a control model you are trying to ask is: does my output match the standard set for it? Or does it reach its target or objective?

Depending on the result of this comparison, you adjust your input to the process accordingly to get the good result.

Purposes of a Control Model

The purposes of this model include:

How to do a Control Model.

In designing your Control Construction, you will use:

- A rectangle to represent the process in question.

- Arrows going into the rectangle or process that represent the Inputs. These inputs can be given titles.

- Arrows leaving the rectangle or process that represent the Outputs. These also can be given titles.

- On the outputs, you can illustrate using black circles the Sensor(s)of these outputs. These are the activities that are carried out to check, to test or to measure the output(s).

- Represented with a large circle, under the inputs section is the so-called Comparator. This is the standard or objective you are going to use in your sensor that checks the output. It tells you the quality of your output, whether the output is meeting the requirements or not.

- Connecting the Sensor and the Comparator, you will have the Feedback loop. This component of the diagram is important. You will need to be clear on how this information is fed back into the process. No point in doing all this testing and to have nothing happen with the results!

- Leading into the comparator are the Standards or Objectives. When you are doing this analysis, it is worth checking whether these standards or objectives are up-to-date, are they the right standards, are they correct? In typical production processes, the question of calibration would arise here. Are your standards calibrated or do they need calibration?

- Finally, you have the Actuator(s). These are, simply said, the means with which you will alter the input(s) so that the process will give good outputs.

Pulling it all together.

It may be well worth considering taking your initial assessment of the situation with the control diagram and writing the information up in table form, with each component of the diagram as a title.

The next step would be to list under each component description, the ideal situation.

This would enable you to do a Gap Analysis. By this I mean, comparing what you have with what you should have and then determining action steps to close that gap.

Remember though that processes are delicately balanced and changing too many aspects at one go can lead to completely negative results that you will not want.

My advice is to slowly introduce changes in a controlled fashion.

Example of a Control Model

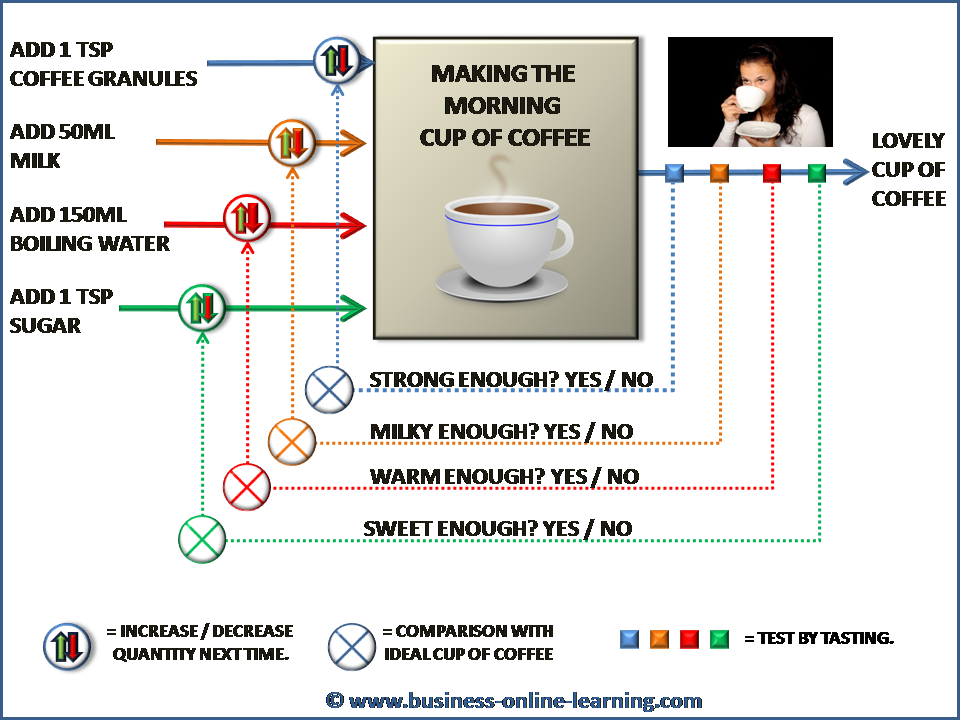

I will admit it, the preparation of this diagram did take some time. I wanted to do it on a very general topic that as many people would understand as possible.

I started out listing the inputs - with a measure (1 teaspoon, 50 ml, 150ml, etc.).

I then listed the target result - my "lovely cup of coffee".

I determined how I was going to check the output from the process to see if it was meeting the requirements, by tasting the coffee.

I then listed the 4 top criteria by which I was assessing the cup of coffee - the strength of the coffee, the milky flavor of the coffee, the heat of the drink, the sweetness of the coffee.

Once I have tested the output using the chosen test method, looking for the state of the coffee with respect to the 4 criteria chosen...I now compare it to an ideal or a standard.

If the comparison is unfavorable, I then adjust the inputs the next time I make coffee. This means, if the coffee is too weak, then the next time I may add one and a half teaspoons of coffee. if the coffee is too strong, in comparison to my ideal cup of coffee, then I take less than a teaspoon of coffee granules.

And that is how you complete a control diagram.

Certainly it takes time, but if you are interested in building a robust process, then this is the method for you.

Business Online Learning Homepage ›

Problem Solving Pages ›

Guidelines On The Control Model

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.