What is Supplier Quality Engineering?

Supplier Quality Engineering is the discipline in managing a company that governs all activities to do with Suppliers and their supplied products or services.

In particular, the focus is on the Time factors, the Cost factors and the Quality factors.

Suppliers should be categorized as to their effect on your company meeting your customers’ requirements. Therefore, Suppliers who have a direct influence or tangible influence on the final product must be evaluated as they are the most critical.

In Supplier Quality Engineering, the aim has to be to assess and reduce to a minimum the risk that any supplier has to your own companies product or service.

Note at this point that while certain suppliers may "only" have a Tangible-to-product influence, they may represent a huge risk to your company if their product or service malfunctions.

In general, Suppliers can be categorized in the following way:

- Direct Influence Suppliers: Those whose Product is integrated into the final product or service of your company, eg. the plastics used in the product, wiring, components, etc.

- Indirect Influence Suppliers: Those suppliers whose Product or Service is not integrated into the final product or service but who will have an effect on the delivered product or service at the customer, eg. the equipment used in the production process, ovens, welding, stamping machines, bonders, etc.

- Tangible Influence Suppliers: Those suppliers of the products that are used up in the product realization but are not part of the final product or service. eg. Cleaning chemicals, in-house transport containers, in-house product protectors, and materials needed to keep the equipment functioning properly etc.

In Supplier quality engineering the product issues can be analysed for their risk-to-quality factor by using a Critical-to-Quality analysis.

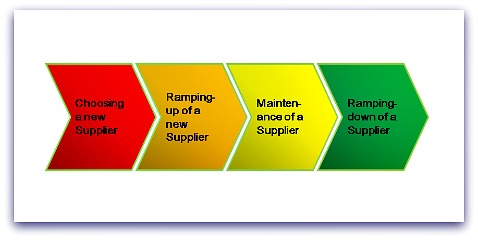

Stages in Supplier Quality Engineering

There are four main stages in Supplier Quality Engineering

- Choosing a new Supplier

- Ramping-up of a new Supplier

- Maintenance of a Supplier

- Ramping-down of a Supplier

In each stage, the programme for securing the quality will be different and must be chartered out. The approach will involve a lot of legal documentation, data analysis and evaluation methods such as:

- Product specification: Details the product or service to be delivered by the supplier.

- Supplier agreements: Contract on the supply of internal results from the supplier’s production, Confidentiality agreements, Just-in-time agreements, Kan-ban, etc.

- Initial Sampling: These are the first samples that arrive from a supplier upon which ability to deliver according to the specification agreed upon. This is extremely important as it is the stage where problems are ironed out on both sides.

- Incoming Goods assessment: This is the continual assessment of delivered goods and issues such as sustainable quality and reliability are key.

- In-Production results analysis (demanding a degree of traceability): This analysis takes place initially as part of the Initial Sampling report and thereafter according to the Supplier Quality Engineering strategy. Each product will have its own risk factor that needs appropriate addressing.

- Data reporting on logistic results: timeliness of delivery by the supplier, accuracy of delivery, Quantity of complaints, Quantity of returns, speed in replacing poor quality items, etc.

- Response times to issues needed to be addressed. Turnaround times in new developments.

- External Criteria would include, Quality Audits at the supplier, Certification according to a Quality Standard, other 3rd party audit results (for example, audits carried out by competitors), etc.

Conclusion to Supplier Quality Engineering

Supplier Quality is key to a companies quality and needs to have a multi-disciplinary approach. The information needed to have Suppliers managed well will come from all areas of the organisation, Production and Purchasing being the two most important.

The key aim of Supplier Quality is to reduce the risk caused by a Supplier. The tools necessary to do this are many and the skill is to use the correct ones at the optimal time.

Go to top of Supplier Quality Engineering page

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.