Guidelines on Input Output Analysis

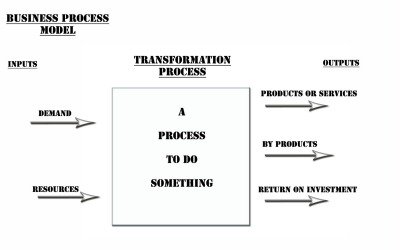

The Input Output Analysis is a way of showing the connections between the inputs and outputs of a process to the process itself.

A simple diagram, it can be seen as an overview method that lists the inputs and the outputs. From this basic method, many others are derived. See Process Management

What is their purpose?

The purposes of an this analysis will include

- To define the outputs resulting from a process

- To determine the process that gave these outputs.

- To define the necessary inputs that are used by the process to be transformed into the outputs.

How to do The Input Output Analysis

Here is the basic concept:

- The Outputs, consisting of - The products or services needed - Any by-products, including secondary effects or secondary product. This will include wastage or scrap - Any ROI, Return on Investment achieved by the Process.

- The Transformation Process is illustrated using a rectangle with the process title or even description in the rectangle.

- The Inputs which are represented using arrows and titles. These can be varied to indicate different groupings of inputs, such as Primary Inputs, secondary input, etc. All the inputs that are needed by the process to function should be listed.

- A Title to the Diagram, indicating what exactly we are talking about here in this diagram.

- If you have used a variety of different representations, e.g. different arrows, add a Legend to explain the different meanings.

When starting out the analysis, clarify the following,

Try out the analysis as a means of getting started.

In fact, I am sure that you will be amazed at the results you will achieve.

Further extensions of the Input-Output Analysis

The Input Output Analysis is a basis upon which you can indeed add on two very important extensions.

1. Controlling The Outputs

Consider what measurements can be made on the outputs. Then define what is acceptable and what is not acceptable in these outputs.

Now create a connection back to a particular input, by asking yourself: "Which Input influences this output?"

Now, decide on actions you will take if your output is not acceptable. Should the input that lead to this output be modified, replaced or improved in some way?

2. Developing Your Process Model For Process Management

The above input-output analysis diagram can be compared to an overview picture, a real process model will entail a lot more details and aspects of a process.

From the above basic model you can zone in on particular aspects of a process by adding - or emphasizing - elements of the process.

Consider the following:

Are inputs accepted in any way?

Are there final approvals that are critical after the transformation process that need to be noted?

What are the key tools of managing a process that need to be considered? What is the strategy (or plan of action) with this process? What will the effectiveness or the efficiency of the processes be managed?

Are there so-called (and seldom mentioned) "Side-effects" of the outputs. In the first instance, we think here about the idea of environmental control, but this will also include such topics as reputation, loss of customer good will, influence on stock market sentiment, etc.

Summary

The input-output diagram is a handy analysis tool that looks at the inputs and outputs to any transforming process.

It can be used in this simple overview form or can be extended to include more details and these are typically called control diagrams or Process models.

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.

My name is Martha and I have worked for over 30 years in various aspects of business and in various countries, right around the world.